Popular Products

Contract Moulding

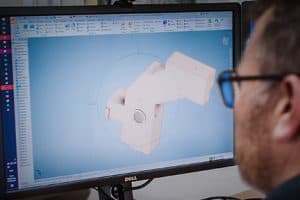

Rotational moulding is one the most versatile manufacturing methods. For many applications, it has become a more cost-effective and manageable alternative to metal fabrication or GRP. We offer a friendly and helpful service, from inception to finished product.

Our Products

We specialise in rotational moulding, producing a wide variety of agricultural and industrial products such as our renowned range of Calf feeding equipment. We have continued to add to our portfolio of ATV accessories and specialised water tanks, including our new underslung tanks for campers.

Experts in Rotational

Experts in Rotational